Future Hydraulics

Kawasaki is constantly evolving, building on our expertise to meet the growing demands of modern applications. As industries push for greater efficiency, we pioneer advanced hydraulic solutions that enhance control and power while driving efficiency.

Designed for maximum durability and reliability, our next-generation hydraulics ensure machines run longer, smoother, and more efficiently

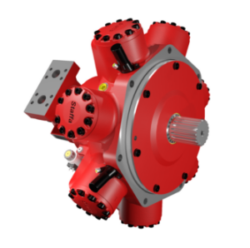

Staffa Smart Motor

Prototypes now available

- Closed loop electronic displacement control: any displacement is possible between motor max and min, offering multiple operating modes from 1 hydraulic motor

- Continuously variable displacement: hydraulic motor reliability, but now with the controllability that was only previously available from an electric drive & inverter

- Electronic communication to and from the motor: easily access data on motor speed, torque, shaft power, displacement; as well as being able to use this data to control the motor – for example set the motor to hold a torque value

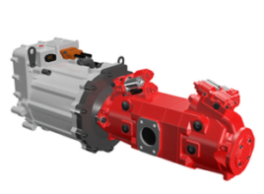

K-Axle

Under Development…

The K-Axle is the all new high speed electric motor and pump unit for construction vehicles. A scalable 50cc single or tandem unit able to operate at speeds of up to 5,000 rpm

- Compact size

- High efficiency

- Highly flexible

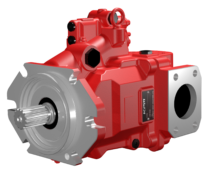

K3VLS Smart Pump

Under Development…

Digitally controlled axial piston pump with electronic controller- Designed to satisfy the next generation needs for mobile construction equipment

Initially the control type will be introduced for the K3VLS85, then expanded to the complete K3VLS range. In the future the control type will be introduced for the K3VL pump range.

- The controller can achieve multiple regulation types ( Variable pressure cut off, Load sense delta pressure control, flow control positive or negative, Torque control).

- Opportunities to optimise hydraulic system efficiency and control.

- Easy to integrate with machine control systems reducing development time.